Electronics production

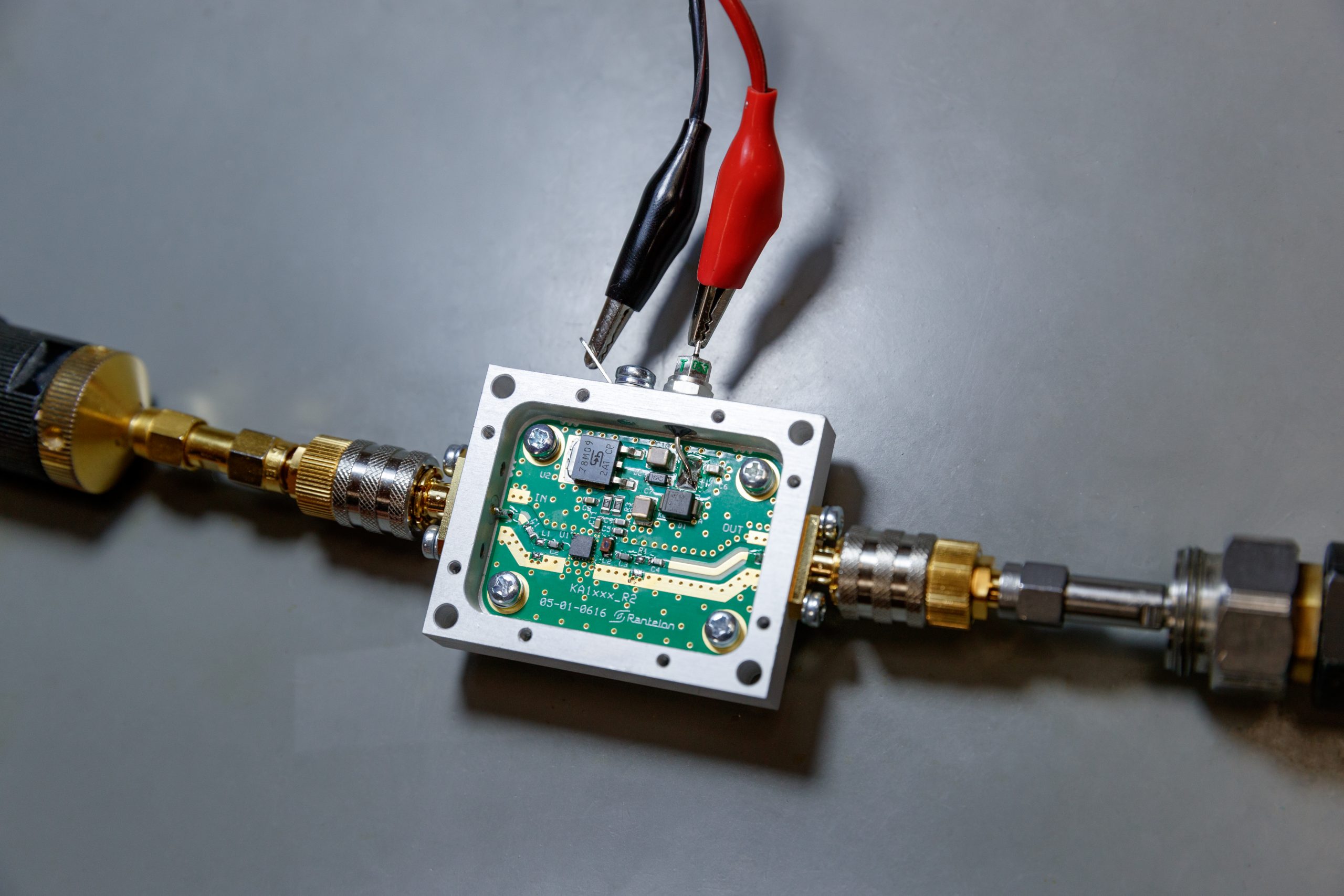

Rantelon produces electronic devices for various users and industries as both its own production and on a subcontracting basis. A subcontract can be agreed for a full cycle or as separate steps – design, production, tuning, repairs, etc. Production is certified and follows ISO standards. Over 90% of all of our products are exported.

Rantelon offers a full cycle of electronics production – from circuit board and mechanical part design to organising the logistics of the entire production process. Rantelon is a trusted and flexible production partner with 25 years of experience.

For the best results, we use the following machinery:

- SMT production line

- selective soldering line for TH components

- automated optical inspection (AOI)

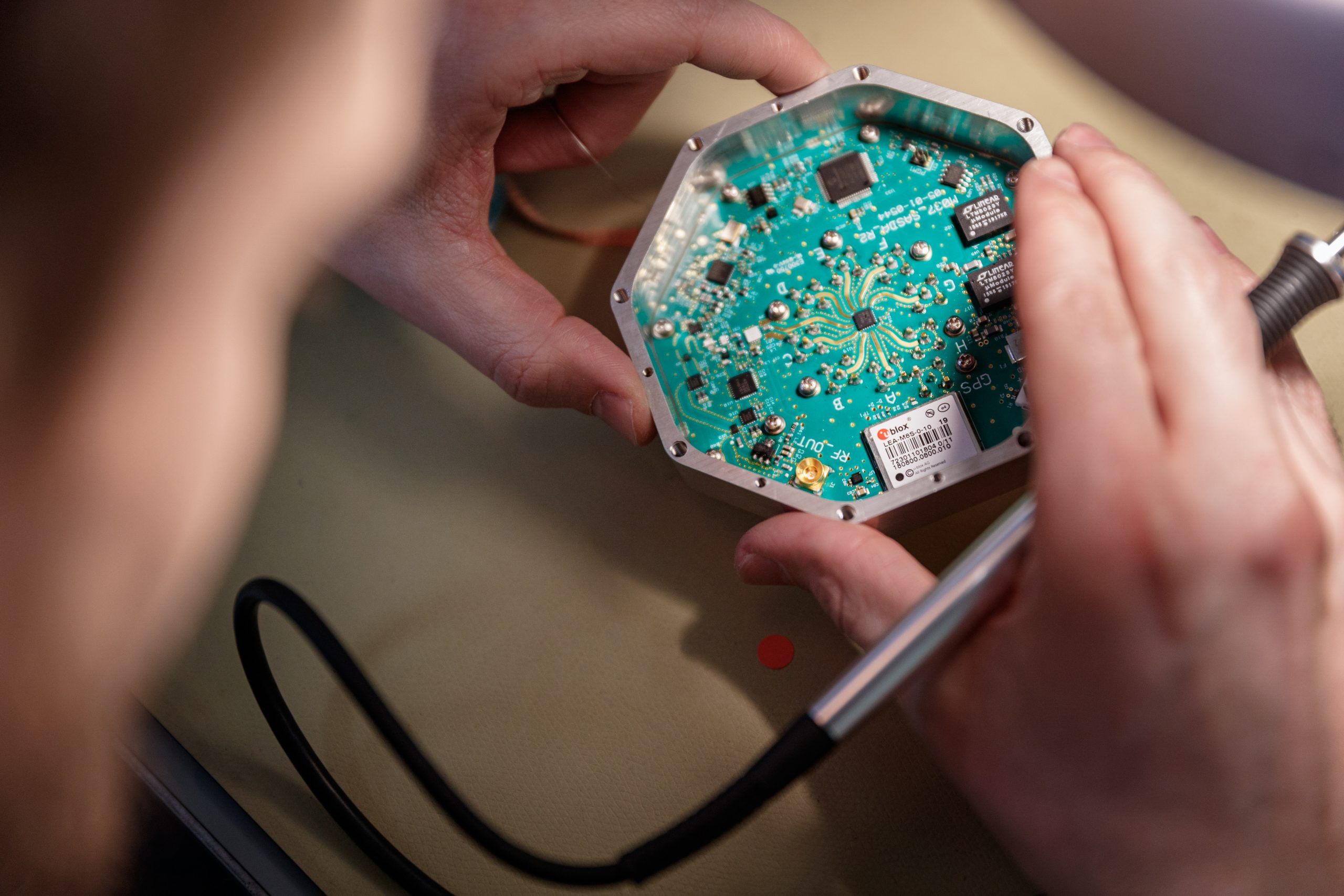

- different functionality testing devices

- constantly expanding list of devices

Electronic component handling and maintenance is carefully carried out following all protocols in a strictly controlled environment.

We can also make product casings, cooling elements, antennae and other mechanical components as per the client’s request. These are made using modern equipment such as CNC mills and lathes and adjustable angle notching machines. For materials, we mainly use aluminium EN-AW-6063, EN-AW-6082 and various plastics. Technical files are designed in the 3D modelling programme SolidWorks. Our engineers regularly participate in further training on the use of the programme.

All of our assemblers have completed internationally recognised IPC standard courses. To ensure that our products and services are of the highest quality and meet all requirements, and to guarantee the efficiency of our operations, we use an ISO standard management system.

Contact our expert here

Maire Kokk

Production Manager

+372 681 3655 production@rantelon.ee